You're A Designer But Don't Know A Four-Harness Weave?!

You really need to start by understanding the basic principles of weaving. As you'll discover in the last article I wrote, weaving is done by interlacing the threads of the warp with those of the weft. What do you won't find in that article, is that harness looms can be categorised into two different "shedding" methods:

You know I'm a stickler for us designers empowering ourselves with amazing knowledge so we can design smarter and better - well, did you know that most plaids are four-harness weaves? If you didn't know that then you must read on!

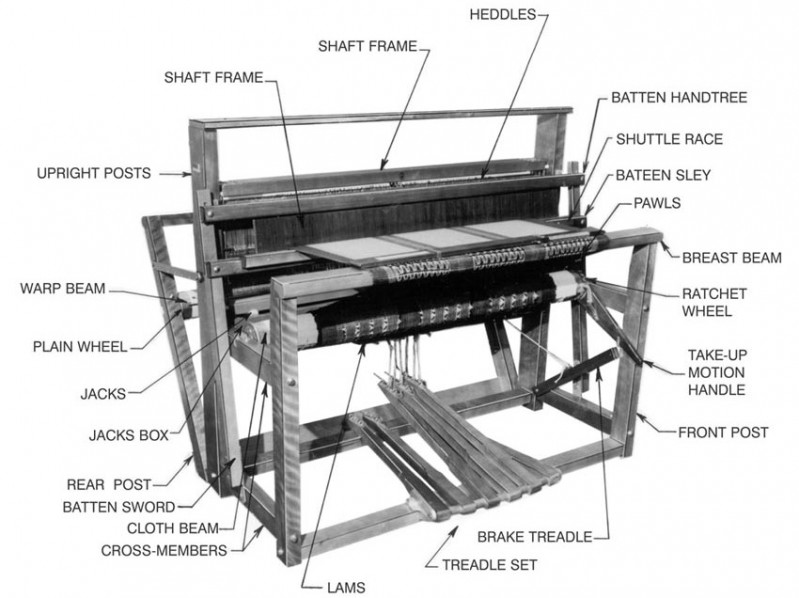

N.b. The "shed" on a loom is the space between the heddles (refer to the image further below if you need to jog your memory!).

Professional Weaving Drafts

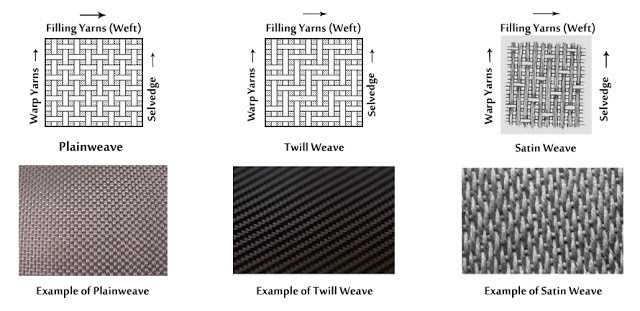

Here's a really helpful diagram from Penelope Walton Roger's book, A brief guide to the cataloguing of archaeological textiles. On the right (the bit that looks like a checkers board) is a professional weaving draft! A black square is called a "float" and a white square is called a "taken". A float shows where a weft thread goes over a warp thread. A taken shows where the weft thread goes under the warp thread.

This diagram illustrates how a plain weave fabric or a "tabby" fabric is woven.

Two Harness Weave - Aka Weaving With Two Harnesses.

On a loom with two harnesses set up, one harness carries the odd numbers and the other harness carries the even numbers of threads. The harnesses are raised one after the other, and the shuttle passed through. Examples of a two harness weave are pain weaves or tabby weaves. By passing two threads on the first harness and two threads on the second harness and then repeating this you would create a basket weave. You can also create a basket weave by using two shuttles and passing them on the same shed (the space between the heddles).

Four Harness Weaving

Interestingly, a four harness loom can still be used to weave plain weave structures, where the first and third harnesses are raised and lowered in opposition to the second and fourth harnesses. Most notably, however, the four harness weave can be used to weave plaids and twills. This is done by raising or lowering only one harness at a time - this method can vary depending on which type of loom is being used, and whether a shed is raised or lowered to be opened. You can do significantly more complex weaving patterns the more harnesses a loom has.

Along my research travels, I came across this astonishing blog Evas Weaving, which I insist you check out if you're interested in learning more! She showcases some of the drafts she's created herself alongside the final products she's woven herself - crepe weave scarves made out of Tencel - right up my street!! As her newest, biggest fan, I immediately got in touch with her and to my groupie joy, she responded:

I really enjoyed reading "Weaving: What are Looms?" I weave on a 16-shaft Macomber treadle loom, similar to the 8-shaft jack-type loom that you show in the first photo with all the parts. I often push my loom's limits to weave patterns that are usually woven on compu-dobby looms by most handweavers.

I'm delighted that you want to add a link to my blog in your article. My home page is the best link and people can browse through what interests them the most.

It's an incredibly fascinating process and Eva documents it all beautifully, so please do have a look!