Do You Know The Effects Of A High Twisted Fibre Fabric?

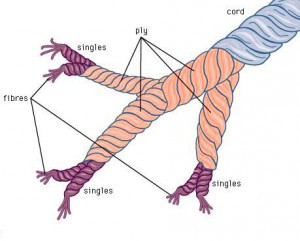

Twisting is simply the process of combining together multiple fibres, threads or yarns in a wrapping around (twisting) motion. Twisting fibres will create a thread (or singles), twisting threads will create a yarn, twisting yarns will create a cord or cable - and so on.

I'm a huge believer in knowledge is power. If you don't know how a fabric is constructed, how will you be able to design a product that is suitable for your customer? Do you know what a "racked" garment is? Do you know how to fix it?

We've already had a quick look at microns, so let's start from the beginning with "Twisted Fibre Fabrics".

What Is Twisting?

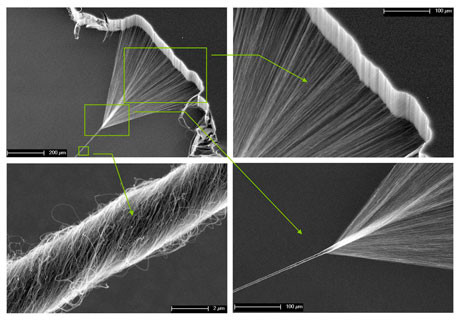

Wool fabric is a good example of twisting fibres, as after a wool is washed and carded, the incredibly fine fibres, particularly of very soft wool, will usually need "twisting" together to become stronger. Fibre twisting takes place during the spinning process.

The twist binds the strands together, which therefore contributes to the strength of the yarn. The number of times a single is twisted, defines the appearance and the strength of the end product.

What Happens If Fine Fibres Aren't Twisted?

Tightly twisting fibres together can also create a lighter and more breathable fabric, that are ideal in summer and hot climates. Tightly twisted fabrics are also incredibly good at springing back - which prevents them from wrinkling and allow for excellent drape.

Did you know: A two-fold twisted yarn has not only approximately 20 per cent more tensile strength and more extension than the two single yarns together, but even more than the equivalent thicker single yarn!

How Many Twists?

Okay, here it starts to get technical. You may not ever need to use this, but I'm a huge fan of submersing yourself in as much knowledge as you can! At each stage of manufacture, the amount of twist in a thread is denoted by a figure. This figure is literally the number of turns of twist per unit length at that stage. This number will affect the characteristics and properties of the final product, including its appearance, behaviour and durability.

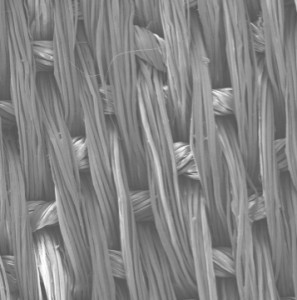

Good to know: Warp yarns, which are the threads used for the length of the fabric, are given more twists than "filling" yarns which run across the weft (the width).

Unit of Measurement

- Number Metric "Nm"

- Number English "Ne"

- Tex-System

Nm and Ne are lengths. Tex is a weight.

Nm: How long the fibre must be to weigh 1kg. For example, Nm100, means that the fibre is 100km long to weigh 1kg. If another fibre is Nm80, then you know it is heavier, as it only requires 80km to weigh the same amount (1kg).

Ne : How many 840 Yards there are to create 1 English pound. For example Ne 60 means that 1 English pound is 60*840yds = 50,400 Yards. (Do NOT ask me where this came from... bizarre!)

Tex: how much the fibre weighs be to be 1km in length. The official tex-system has recently caught on and is really the "go-to" for manufacturers.

Silk Machine Twist

As if we didn't have enough options, silk machine twist size is another unit of measurement (also by weight). In this case, the sizes are given as letters rather than numbers, ranging from 000 through A through F and then to FFF. Exactly what length a given letter means depends on the manufacturer of the thread (of course it does.) but there is a fairly common understanding of A, B and F.

- Size A is a general-purpose thread

- Size B is for heavy seams

- Size F is for worked buttonholes.

There is another letter-based thread size system used in US government contracts. Its sizes are very roughly the same as the silk machine twist system, which makes it easy to confuse the two. In this system, size 00 is about T-16, size A is about T-24, size AA is about T-30, size B is about T-45, size E is about T-70, and size F is about T-90. These sizes are controlled by formal specification, not the whims of thread makers. Make sure you clarify with a manufacturer which system you're using!

That by no means exhausts all the thread sizing systems still in use (but it's exhausting me!) so here's a useful table to help:

A Quick Chart of Threads & Associated Weights

| Very Fine (Blindstitching) | Fine (Heirloom Sewing) | Medium (General Sewing) | Coarse (Topstitching) | Very Coarse (Hand Buttonhole) | |

|---|---|---|---|---|---|

Cotton Count |

80/2, 120/3 |

60/2, 90/3 |

30/2, 45/3 |

17/2, 25/3 |

12/2, 18/3 |

Tex |

T-15 |

T-20 |

T-40 |

T-70 |

T-100 |

Metric Ticket |

200 |

150 |

75 |

45 |

30 |

Denier |

135d, 68d x2, 45d x23 |

180d, 90d x2, 60d x3 |

350d, 175d x2, 117d x3 |

630d 315d x2, 210d x3 |

900d, 450d x2, 300d x3 |

Linen Count |

225/2, 335/3 |

165/2, 250/3 |

85/2, 125/3 |

45/2, 70/3 |

35/2, 50/3 |

Silk Machine Twist |

- |

000 |

0, A |

E, EE |

F |

Appropriate Needle |

9 / 65 |

10 / 70 |

14 / 90 |

18 / 110 |

20 / 125 |

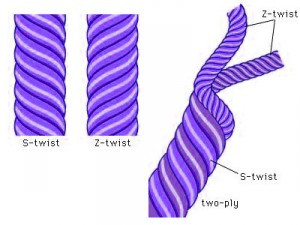

Know Your Twists

You can twist a fibre in two directions. During manufacture, the direction of the twist is indicated using the letters S or Z. A good tip here is to look at the centre of each letter. Ignoring each end of the letters, have a look at the direction of line right in the centre. You can see the “S” runs (from top to bottom) left to right and the “Z” runs (from top to bottom) right to left. When you hold a thread vertically, you will see the twist runs in either of these two directions. That’s how you know which twist has been used!

Tip: "S" and "Z" twists are used whenever threads or yarns are twisted. Even cables will be "S" or "Z" twists.

Which Twist Is For What?

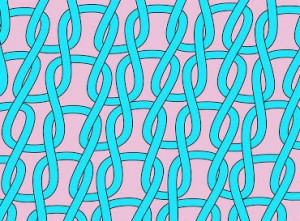

For tights, manufacturers nearly always use an “S” twist. In fact in knitted fabrics, Z-twist yarns are very rarely used. Single strands of yarn, however, are normally twisted using the Z-twist.

This is a little complicated, so I’ll try and explain it as best I can!

When Z-twists are being plied (twisted) together, you would do so with an S-twist (as shown in the diagram above). This is to prevent any warping of the yarn. So, if you took a three- or four-ply wool yarn, you’d see it had an S-twist (usually anyway!). If you untwisted these four plies (individual yarns) and examined one of the singles, you’d discover it was spun with a Z-twist!

Let’s go even further: If this four-ply yarn was combined with more four-ply yarns to create a cable, they would be twisted with a Z-twist (refer to the diagram below). Alternating the twists like this, creates a strong and balanced yarn.

Quick Fabric Examples

- Soft surfaced fabrics: slack twist.

- Smooth surfaced fabrics: optimum twist. This promotes strength, smoothness and elasticity.

- Crepe fabrics: maximum number of twists.

- Poplins: two single yarns that are Z-twisted individually and plied together using S-twist.

- Sewing thread: three S-twisted single yarns, then Z-twisted together. This will create a tear-resistant thread !

- Voile: a spun fibre which is twisted in Z direction. The twisted yarn is also twisted in the same direction as the spun fibre (z direction). This create a high twist yarn with a tendency to curl. The fabric it creates is transparent and robust. This is why curtains are often made from voile. To get even more transparency and also to produce vibrant colours the finished twisted yarns are sometimes "gassed". This is where any fibres that stick out are burnt off.

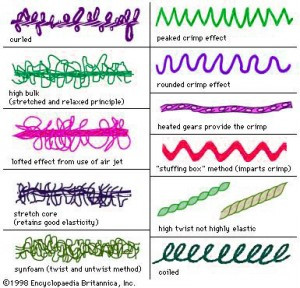

- Fancy twists or nub yarns: made from different kinds of components such as nub, loop and other effects and are produced on special machines.

And Here's How You Can Impress Everyone!

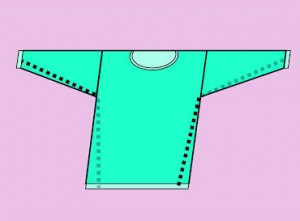

If you’re working with a singles yarn, spun with an overly tight twist, it will usually lean or bias when knitted. Biased fabric is incredibly common. Commercially knit garments often suffer this problem, and it is most obvious when you see sweater seams not hanging straight, but instead, spiraling around the torso of the wearer. Sometimes, not only do the seams spiral, but the entire garment is biased or “racked“, as is shown above.

Hand knit garments, sadly, can also suffer this problem. Luckily, if you're hand knitting, this can actually be rectified (unless it's your yarn that's been overly twisted... sad times). Either way, you can at least avoid ADDING to the problem!

Hand Knitters Beware!

This is an amazing piece of knowledge when it comes to winding yarns into a ball. If you center-pull yarn from skeins or cakes, you will get twist - noooo! IF, however, you always unwind cakes or skeins from the outside, AND smoothly unspool caked yarn via a lazy susan or core-and-spindle, then winding and rewinding will not twist the yarn - hurrah!

If your knitting product has become biased, this can’t be corrected by blocking. You’d have to work with this yarn in a combination of knit and purl stitches. Similarly, if you’re yarn coils and kinks after it’s been wound it into a ball, you probably winding it against the twist – trust me, knowing this will save you hours of trouble!

TIPS: When using a ball-winder to wind from a skein, the yarn being re-wound must not be pulled from the centre of the skein, or you'll twist the yarn. Always unwind from the skein's outside.

Yarn from cakes that will be unwound for either knitting-up or further re-winding must be smoothly unspooled from the outside. Try doing so using a lazy-susan-type device with a spindle onto which the yarn cake is impaled, and which, smoothly spinning, unspools yarn from outside the cake when the outer yarn end is pulled or... a toilet-paper holder (or similar spindle) onto which the cake--having first been wound onto a toilet-paper core--is placed to smoothly unspool the yarn from the outside of the cake!

Amazing Knitters Tip:

Put your yarn cake into a teapot and pull the outside strand (not the center strand!) through the spout. The teapot will keep your yarn from rolling off into the distance, and your yarn won't get twisted because you are pulling from the outside. Try it! You do need a teapot with a big enough opening for your yarn cake. Plus... the teapot looks super cute next to your knitting chair! The slight downside is that if anything goes awry with your knitting, you'll have to cut your yarn-in which case you might like to stick to a more aesthetically pleasing tupperware box with a nifty hole in the lip of the lid for your yarn to sneak out.

Using Twists To Your Advantage

If your yarn is overtwisted or under twisted or your final product is “racked”, why not use twists to your advantage?!

Suppose you're hand knitting and you've got yourself an overtwisted S-twist yarn - arrange your cake so you're pulling the direction that imparts a Z-twist, and you'll partially correct that and make the knitting more pleasant (arrange it the S-twist way though and it's Telephone-Cord City for you!!). And if you've got an under twisted Z-twist, which is wanting to come apart on you, then arrange your cake to add a little more Z-twist, and that problem should stop. And, of course, you can address overtwisted Z-twist and under twisted S-twist by pulling from the S-twist side... a little complicated, but an awesomely clever way to get your products looking tip top!

Who knew fibre construction could be quite so complicated?! But with these tips and tricks, you can really create products that are a much higher quality and last much longer than they would have if you hadn't known. Sign up to my monthly mailinglist to receive a round up of the most popular stories!