Fabric Made From Fungi

We are firm believers that the future of fashion has to be in sustainable, eco-friendly materials and designs. From fabric created with recycled PET bottles, to man-made spider silk, conscious designers have been experimenting with various non-polluting, biodegradable fabrics with low environmental footprints in their designs.

Fabric made from fungi is one of the newest additions to this list of sustainable innovations. This futuristic fabric is interesting in many ways. Generated in a lab, it is strong, durable and can be mended easily. It is skin-friendly and doesn't need sewing. And the scope of the fabric doesn't end there...

Amazing fabric made from... mushrooms?

How Can Fabric Be Made From Fungus?

Fabric made from fungus is created by a technical process known as bio-fabrication. This is the process of growing materials from small organisms like bacteria and fungi, and is a revolutionary and fast-growing sphere of science. The most exciting part of this concept for us, is how it's bringing fashion closer to biology, as scientists and designers work closely to create clever fashion solutions.

Different material combinations are used to create different types of fabrics from fungus. One of these is growing it from mycelium—the root structure of the fruit that is a mushroom (it grows underground so is rarely seen, but will communicate between plants to keep micro-organisms and plants healthy; it's quite magical!). Muskin is one such fabric, from Grado Zero Espace, and is a possible substitute for animal leather and suede, and has already been used in accessories, bags and shoes. Ecovative also now have a solution known as Forager Hides™ (article updated 2021) that are very similar to Muskin in look and feel - but as these materials are not fully commercially available, getting information is difficult.

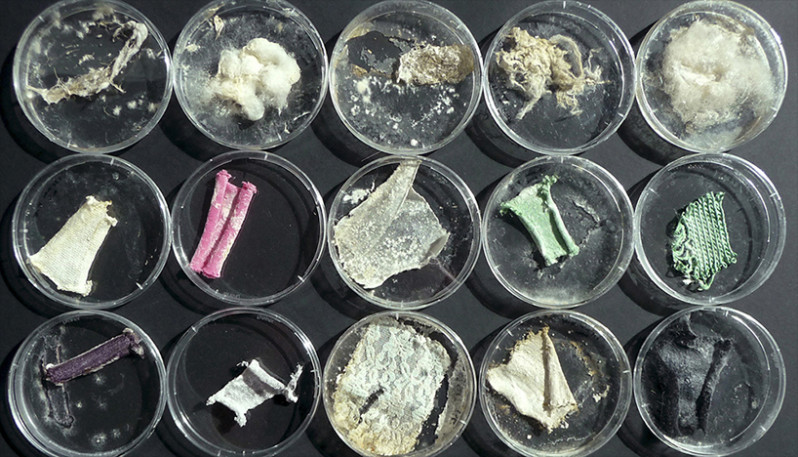

The Dutch fashion designer Aniela Hoitink created a showstopper dress with a fabric called MycoTEX, which is made from mushroom root i.e. mycelium. She used petri dishes to supply nutrients that will grow the root of a common mushroom into disc shapes. The discs are then overlapped to form a thin fabric that is shaped into a dress on a mannequin. The advantage of this fabric is that the dress comes together without sewing. Tears and holes are altered by simply placing patches over the hole, and covering up the damage easily.

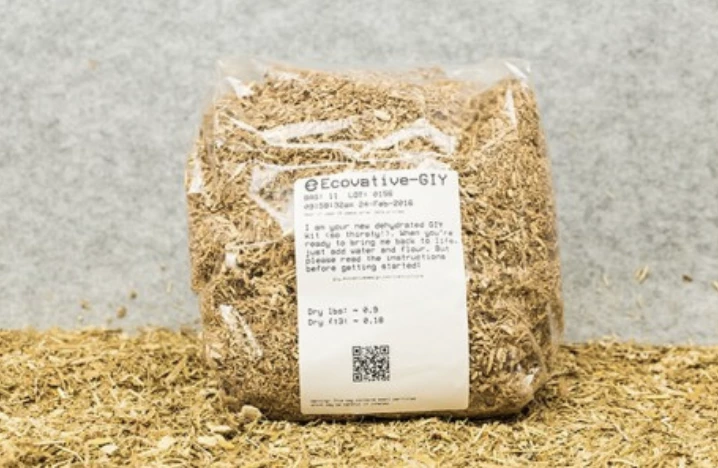

Mycelium can also be grown into fabric or hard material by breeding it in a suitable environment composed of agricultural waste like straw, as shown by BIOHM (you can also access a lesson from the BIOHM team that looks at biomimicry here). In addition to the sustainably-sourced raw material i.e. straw, the method requires a tiny amount of energy. The process is similar to fermenting in that you let bacteria do its thing, and different designers have used substances like green tea, sugar, yeast and bacteria to make a variety of fungi fabrics. And as mentioned above, the Ecovative team have also created MycoComposite™, which is a similar blocky biodegradable-but-durable building material (actually shown at the Mushroom exhibition at Somerset House in 2020). If you were also present at the Food: Bigger Than The Plate exhibition at the V&A Museum, you would have seen these straw bags hung up growing oyster mushrooms, though this fruit was more for eating than wearing.

Fungi #fashion?..We've got the facts!! #eco #sustainable #leather #design

Characteristics Of The Fabric

Fabric created from mycelium is non-toxic, waterproof and fire-resistant. Since only the root is used for the construction, it lacks spores and doesn't continue to grow (though we personally think that could be cool). The textile either feels like paper, but is flexible and comfortable to wear, or otherwise sort of spongy and leather as in the case of Muskin.

The material is anti-microbial and is suitable for sensitive skin - there are no additives, it is literally just an organism. Additionally, in production it uses very little water (though in reality, you will only get mushrooms - the fruit - when it has been raining). For the production of her MycoTEX dress, Hoitink used only 12 litres of water. To put that into context - the production of a cotton t-shirt uses almost 2500 litres of water!

Another desirable environmental benefit is that it is easy to dispose of the dress when you do not want it anymore. The biodegradable properties ensure that the fabric returns to the earth without causing any pollution, in a beautiful soil-to-soil system (learn about the benefits of this in our panel discussion with Babs Behan and Jen Hunter, a maker and farmer following the Fibreshed movement).

Designers who have used fabric from fungus in their designs

You have already been introduced you to Aniela Hoitink, who used MycoTEX from mushroom root in her innovative design, however she isn't the only one who has tapped into the interesting world of creating fabric from fungi.

Another interesting example of someone exploring this fabric to the full is artist in residence at Microsoft Research, Erin Smith, who produced her own wedding dress using tree mulch and mycelium. She sets a fine example for sensible fashion choices, which are both sustainable and stylish. Smith decided to make her own wedding dress after concluding that wedding dresses were an expensive investment that would be used just once.

Another notable designer is Suzanne Lee (we talked about her amazing tea fabric in my last post!). She is the director of Biofabricate, a company driven by the idea of creating fashion with microbe fabrics, who coined the term "biocouture" and now also hosts an international bio-tech conference. Biofabricate works with brands to apply the technology of bio-fabrication to sportswear and luxury products. Lee is also the CCO at Modern Meadow, a progressive company that focuses on providing a viable leather alternative to animal hides by growing and engineering fibres made from collagen in their lab to form leather-like material structures (learn more in these TED talks).

#Eco #fabric made of mushrooms!! #sustainable #leather #design

Although they touched upon a number of ideas at the conference in 2015 (the year before this article was originally written), growing structures from fungi was the core topic. One of the companies attending was Ecovative, mentioned above, and we can see now how much they have developed with research, interest and demand for alternative materials.

At one point, lighting designer Danielle Trofe had grown and developed a collection called MushLume from Ecovative's Grow-It-Yourself kits, though now there are MushLume kits (amongst others) for you to purchase to try yourself.

Challenges Of Using Fabric Made From Fungus

The environmental benefits of this fabric are pretty obvious when you consider how much synthetic and mined waste we get through. However, there are certain factors that challenge the scope of this product. Firstly, the current manufacturing process is time-consuming and laborious. While Erin Smith took a whole week to grow her dress, Suzanne Lee's method required anywhere between two and four weeks to complete. This aspect can make it very difficult to create fabric on a commercial-scale for production needs. The issue with the producers wanting to work with you is also key; some are just not ready to share their product and so you may have to go it alone (Materiom are a wonderful open source library that can teach you some tricks; listen to our panel discussion with two fantastic material researchers, Zoë Powell and Alice Robinson as well to learn more about the pros and cons of bio- or classic materials).

The other factor is acceptance by consumers. Since the raw material can often be "waste" - or not just that, often connoted as mould - not everyone is excited about fungus-grown clothes. If consumers are educated to overcome their aversion and instead recognise the unique benefits of this fabric, it is likely that fabric from fungus will be a lasting solution for many of our sustainable fashion needs.

For all the latest news and announcements and make sure you sign up for our newsletter!

And please do share our article (you can use our very handy tweet buttons throughout).

Wearable mushroom fabrics!?? #eco #sustainable #leather #design