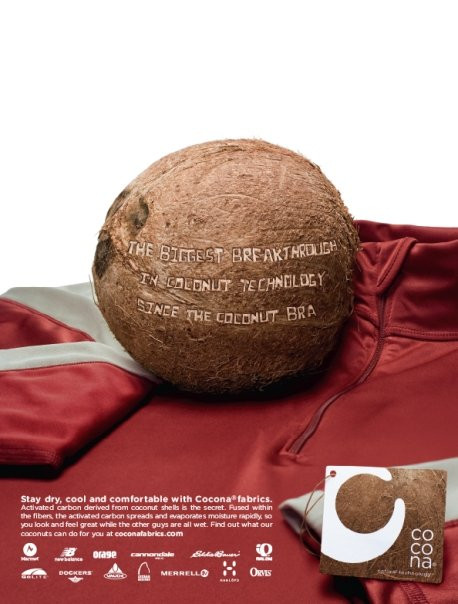

Update in Sustainable Fabrics Development - Using Coconut!

Coconut is widely known for its health and beauty benefits. It has been used to make a huge variety of products from cream, flour, oil and butter, to hair masks and skin treatments. But did you know that coconut can also be used to make an seemingly ordinary fabric, amazing? Coconut fabric, or Cocona, is taking the textile industry by storm and could be the future of activewear.

#Coconut fabric - a new development in #sustainable #fabrics. Read on folks...

A technological innovation called Cocona is made using activated carbons derived from coconut shells and volcanic sands - both waste products of the food and water filter industries. These particles are impregnated into fibres to give fabrics super powers. The technology was developed by a company called, "37.5". What's with the name?? (I wondered the same thing). It's derived from the the temperature of the human body, which usually sits between 36.5 and 37.5 °C, and the theory that if you’re able to keep your body at this temperature throughout a workout (or any activity!), your level of performance will increase. This is the principle of the technology - keeping your body cool, particularly while you workout.

What's the point of integrating coconut?

To use its enormous absorbing potential of course! According to MetaEfficient the charcoal obtained from coconut shells emits activated carbon which is the secret ingredient that's incorporated into the fibres. One gram of activated carbon has a surface area the size of two tennis courts. So this huge absorption property lends itself to wicking away moisture and absorbing (technically adsorbing) odours. Let me explain a little more. Well actually, let me allow Gregory Haggquist CTO and Founder of Cocona Inc. to explain,

Aside: Adsorption (not a typo) is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. This process differs from absorption, in which a fluid is dissolved by a liquid or permeates a solid. Adsorption is a surface-based process while absorption involves the whole volume of the material. Adsorption is a surface phenomenon.

COCONA uses coconut shell activated carbon. Body odours are molecules such as butyric acid, isovaleric acid and trimethyl amine. These molecules are all similar in size. The coconut shell activated carbon has pore sizes that are just right to adsorb these molecules at ambient temperatures and desorb these molecules at temperatures found in a washer (hot water cycle) and cloth dryers. We verified this by testing the adsorbance capacity of each COCONA certified fabric. The test determines the adsorbance capacity using butane gas. We ran experimental trials where we saturated a COCONA fabric and then washed and dried the fabric 50 times. We found that the adsorbance capacity slightly increased over the 50 cycles. The capacity increased because more of the pores of the coconut shell carbon became exposed. The reason for this is in the patented process TrapTek used to make COCONA yarns and fabrics. TrapTek uses a protective layer which coats the carbon during the processing of the yarn. If no protective layer is used when the polyester polymer is melted to be formed into yarn the polyester will fill up the activated carbon. In a sense this deactivates the activated carbon. When the polyester solidifies to form the yarn the carbon pores are filled and covered with polyester never to be exposed. However, in the TrapTek patented process we use a protective layer which covers and protects the pores during the yarn processing and fabric production. The final step in the fabric processing removes this protective layer exposing the activated carbon pores. Further washing continues to remove this protective layer exposing more of the activated carbon pores increasing the adsorbance capacity.

Good For The Earth?

Just to clarify - Cocona is not a fabric, it is particles (derived from coconut and minerals from volcanic sands) that are then permanently combined with a polymer base and turned into fibres - like polyester. As a non-renewable raw material and the source of an ever-growing micro-fibre pollution problem, this discovery was a huge blow for me personally. It's a shame that such a brilliant step towards using natural materials as a solution to high-performance activewear is then being combined with an essentially toxic fibre.

Though popular, cotton is not favourable for a whole host of reasons either, particularly because it requires incredibly harmful pesticides to make (which of course organic cotton from yours truly do not contain!). You can read all about why cotton is so bad in a previous article I wrote, but there are plenty of natural fibres that, combined with Cocona, would create the ultimate in sustainable activewear - how about Ioncell F for starters?

One option, that I hope 37.5 adopts soon, is the use of recycled polyester. This textile is made using old bottles. Instead of throwing old water bottles away, that don't biodegrade in landfill and cause significant contribution to global warming, the bottles are repurposed and turned into yarns suitable for garments and home furnishings. You can read more on the benefits of recycled polyester here. Although this wouldn't solve the microfibre pollution problem (which still exists with recycled polyester), this would at least ensure that the fibre was not made using a entirely new raw material.

Despite the use of polyester, it's incredible to see the textile industry embracing natural raw materials as an eco-friendly alternative to current chemical treatments (I wrote quite a fun article on other fruit-based fabrics that you might enjoy too). The great thing about Cocona is that it's all natural and made from by-products - so that's a step in the right direction.

A fabric made using #coconut #charcoal and volcanic rocks!? #geology gets #fashion!

Inherent Properties

The creation of Cocona through what is patented as 37.5 technology has numerous desirable properties.

1. Dries quickly: Whether from washing or sweating, the fabric quickly wicks away moisture, so it dries in a significantly short period. This is because the pore structure of the active particles increases the surface area of the fabric. In fact, the technology allows the fabric to dry up to 92% faster than even recycled cotton - read more on recycled cotton here. This could also mean electricity savings for those who still rely on tumble driers in our current environmental climate.

2. Controls odour: Odour molecules are absorbed by the pores of the fabric. The molecules are cleared completely when the fabric is washed and dried.

3. Highly durable: Cocona fabric is proven to last longer than most natural sports textiles like bamboo and cotton, as the particles in the fabric are so wear-resistant. While it is near impossible to wash away the Cocona particles, micro-fibre pollution, caused by the washing of synthetic textiles, is a huge environmental problem.

4. Protects from the sun: The fabric offers the skin a shield from harmful ultra violet rays. The protection can be up to 50UPF+ (Ultraviolet Protection Factor). The active particles also absorb harmful UV rays.

5. Wrinkle-resistant: This feature makes the garment look presentable even if it hasn't been ironed. This is a great benefit for travellers.

While I've found numerous references to a study verifying its fast drying properties, which you can see here, I'm yet to find any studies on (and proof of) the remaining four properties that the fibre boasts. The technology is (as you can imagine) kept firmly under wraps, so I may just need to dig a little deeper and prod a little more!

Coconut fabric full of desirable properties. Tell me more @OffsetWarehouse!

The Ideal Workout Wear

As we read above, the properties of Cocona fabric makes it ideal for sportswear. It's long-lasting as the active particles do not wear out. It also dries faster. Plus, it's odour absorbing property means that it masks unwanted body odour during a sweat-inducing workout.

SunSlave suggests that it is particularly advantageous for fitness enthusiasts who like to get active outdoors because (as previously mentioned) it is UV resistant. Plus, it's very light and comfortable to wear. The fabric yarns can be made in a variety of thickness and weights, and woven or knitted in any way - which makes the end fabrics completely adaptable to almost any garment.

Waiting For Liftoff

There are only three cons. Firstly, the polymer-base that we discussed previously. Secondly, the enormous transport emissions from shifting the raw material from countries where coconuts grow to countries where Cocona is produced. Although, if we hurry up and kick our fossil fuel addiction and switch to renewable, this could no longer be an issue. Thirdly, because it's still a relatively new technology; few people are aware of it. Thus, only a handful have embraced it. Thankfully, the business is growing gradually and many outdoor clothing companies are beginning to slowly apply this technology. Most report that they prefer it and as a result are becoming less reliant on synthetic coatings. Companies like Polartec, Marmot, and Orvis have incorporated the new textile technology. More recognisable brands like Adidas, Under Armor and North Face are also starting to use Cocona fabric.

This fabric is absolutely incredible and most definitely in the spotlight for the future of the sportswear and so the sooner more companies embrace it and the sooner the company can work with more ecofriendly fibres, the better.

I'd be delighted if you used the button below to tweet this article if you found it interesting!

Sustainable fabric development of the week: Coconut fibre?! #ecofabrics

If you enjoyed reading this post and then please sign up for our newsletter! We have plenty of events coming up. You’ll also receive round-ups of our latest blog posts about conscious design and textiles, whilst being the first to know about new fabrics.